What looks like basic everyday packaging, such as paper bags, actually depends on carefully selected materials and thoughtful construction to bear much more weight than most people assume.

The Basics of Paper Bag Strength

When grammage goes up, the fibers knit together much more densely inside the sheet. That compact layering means the paper can spread out pulling forces, squeezing pressure, and twisting motions over a wider area, so no single spot takes all the punishment and risks tearing open.

Engineering Features That Boost Capacity

The paper alone isn’t the full story—clever build techniques add major durability. Handle paper bags often use twisted cords or broad flat strips that spread the load across more surface area, turning potential weak points into reliable supports. In tougher applications, manufacturers layer the walls twice, giving the structure extra thickness and stability to support 10-20 pounds (sometimes higher) without buckling.

Comparing Different Types of Paper Bags

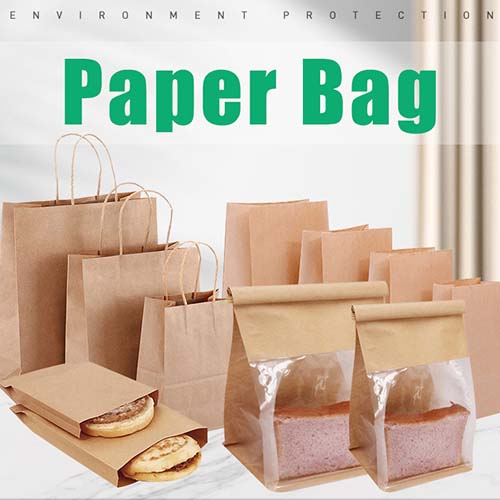

Each style brings its own advantages for handling weight. Square bottom paper bags deliver excellent balance thanks to their rigid, flat foundation, which keeps contents steady no matter how unevenly packed—great for things like produce or glass jars. Sandwich paper bags keep things lightweight and quick but add solid edge support for everyday moderate loads. The eight-sided sealed paper bag uses its multi-faced construction to lock everything firmly in shape, making it especially good for dense, heavy fills that demand containment without distortion. When stacked against plain flat designs, these purpose-built options prove how form and sealing can seriously amp up load capacity.

At Hydenature, our paper bags blend eco-friendly materials with these tough designs. We offer customizable options in handle paper bag, square bottom paper bag, sandwich paper bag, and eight-sided sealed paper bag styles. Contact us to create custom solutions that carry more than you think.